Waterborne heating of the boat

Oil stove

To heat the boat, we use a stove from Refleks (model 2000 kv, which emits a maximum of 4.2 kW divided between air and hot water for radiators).

The oil stove takes the air for combustion from the wheel house, which provides good dry air. Depending on the outside temperature, the humidity in the cabin is between 30 and 40% relative humidity.

The stove runs on diesel fuel from the boat’s fuel tank and supplies heat and hot water (antifreeze) to radiators.

After having got some further development, we are extremely satisfied with the stove.

Cooling the chimney pipe

Made as an extra order from Refleks

With the help of a fan, the chimney pipe is forcibly cooled with air taken from outside. The heated air is sent out into the bathroom. Result: warm and dry bathroom, less heat release to the room the stove is in, and less heat release to the house sparrows.

“Duvet” for the stove

Made as an extra order from Reflex

The selected stove gives approx. 1/3 of the heat to the room, where it is placed (wheelhouse), and 2/3 of the heat is delivered as hot water, which is sent out in radiators to the rest of the ship.

We both have had made an insulated lid to put over the hob and a “belly belt” to cover the upper cooling holes.

By regulating: from no “duvet and belly belt” and belt to full “duvet and belly belt”, we can regulate the heat release in the wheelhouse from wind at night to calm and sunshine during the day.

Elpatron i radiatorvandet

When the outside temperature is above about 10 degrees, the stove produces too much heat, therefore in the radiator water we have installed an electric heater, which is regulated from a thermostat.

The electric heater is made by Alde, and probably mostly intended for caravans, but works just as well for a boat.

Varmeveksler til motoren

Oil stoves, which, like ours, draw the combustion air from the cabin, are unsuitable for use while sailing, as it easily happens that the air flow reverses and the smoke ends up in the cabin. We therefore have inserted a heat exchanger between the cooling water from the main engine and the radiator water (of course with a shut-off tap, so that the cooling water does not heat up in port). It works really well and quickly provides lots of heat .

Ekstra brænder til fyret

Made of reflex as a service repair

We had problems getting the stove to burn quietly and cleanly at high heat output. The problem was solved with a larger burner for high output use. The problem is probably chimney dependent.

Ekstra cirkulation af vandet i kedlen

Made of reflex as a service repair

We have had the problem, that the water inside the stove started to boil at high output without releasing much heat to the rest of the water. The problem was solved with a small pipe that improved circulation in the boiler.

Most boilers have a spiral pipe instead of a boiler, so of course they do not have the above problem, but if you choose the 2000kv model and must have a high flow temperature on the radiator water, it is a good idea to have this pipe inserted immediately.

Other things about the installation of the stove

As a circulation pump, we use an energy-efficient circulation pump from an ordinary house oil boiler. It uses approx. 5W (220V), if we don’t have shore power, it is supplied from an inverter. Unlike 12V pumps, it is long-lasting.

When I installed the radiator system, I inserted shut-off taps, both for all strings, and for two extra strings. One set of extra taps is used for the heat exchanger for the engine, the other set is used for an extra radiator in the kitchen. I have been really happy with the taps on the other strings when changes/repairs had to be made, without them I would have had to empty the water/antifreeze pipes several times.

Links to suppliers:

Insulation of a boat for year-round residence

– Hvordan slipper man af med kondensvand?

Why insulate a boat that is already warm enough?

An ordinary yacht has a small outer surface and can be heated, regardless of how much insulation there is in the boat.

Therefore the main purpose of the insulation is comfort and no condensation, i.e. the surfaces must be kept above the dew point.

If we e.g. assuming we have a relative humidity of 50% (22 degrees), this means that the surface must be warmer than 12 degrees.

How do you do that?

In our boat, I have chosen to put 38 mm insulation material on all available surfaces. That is especially coffin benches and cupboards. And then I have led the radiator water through the coffin benches in uninsulated pipes.

Less might do, but the above is enough.

Insulation material

The insulation material must be so flexible that it can be glued to double-curved surfaces, and it must be vapor-tight. I have chosen Armaflex, but K-flex is roughly the same product.

Imposition

Armaflex has a self-adhesive adhesive surface on one side that sticks very hard. In order to be able to control the application, I have chosen to apply it in two layers of 19 mm.

To get a nice surface I have:

- glued the Armaflex to the hull using contact glue (the built-in adhesive surface upwards).

- The next layer is now glued using the first layer’s built-in adhesive surface.

- At the top I have put a layer of ceiling vinyl, again glued with a second layer of adhesive. Result – a nice and robust surface.

Armaflex

The price differs from country to country, e.g. it is much more expensive in Denmark than in Germany

isolierprofi.eu

Search for Armaflex

Underfloor heating

Why underfloor heating?

We heat the boat with an oil boiler and radiators, so we do not need additional heat. Still, it’s super nice to have a little warmth in the floor.

The underfloor heating comes from heating foil (the one used in caravans).

The insulation mats mentioned below are 3 mm thick and are also used in caravans.

An insulation mat, a layer of foil and a carpet with a thin or medium back site are laid under the table in the salon.

Under the fixed floors (pantry and toilet), two layers of insulation mats, a layer of foil that overlaps at the joints, and finally the fixed floor are laid. All glued together into a compact unit.

A few foil remnants have been used under the mattress in the corner of our bed (there was a thermal bridge towards the hull that could cause condensation)

A dimmer (Opus 66 mek-d 450lr) is placed in front of the transformer so that the floor heating can be adjusted. In summer we use 10-15w/m2, in winter 40-50w/m2.

Note: the dimmer must be for inductive load, if you use one for Ohmic load it will break.

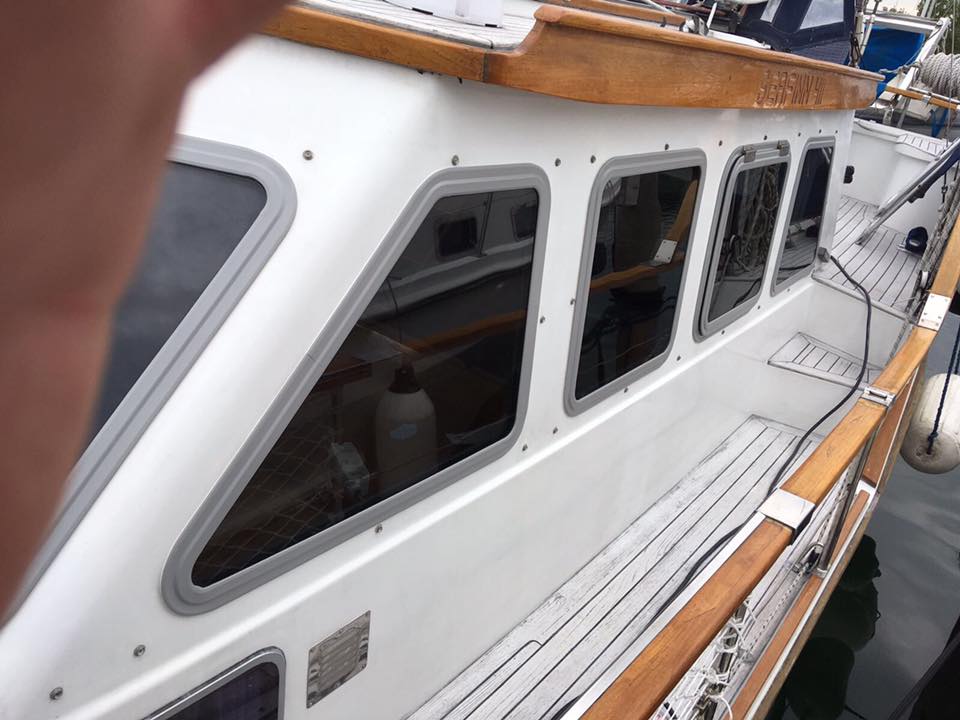

Double glazed windows/inner frames

Do your windows also run on condensation when the summers humidity is high or the temperature drops outside? Ours no longer does.

Inner panes

In our wheelhouse there are a total of 13 windows with an area of 3-4 m2. Over several years, we have tried with inner panes made of 4 mm lexan.

The insulation performance of these inner panes has been excellent, but we had quite a few problems with mist between the panes. To absorb the moisture (dew) between the panes, we placed a small bag with silica stones.

We have had two types of inner panes:

- Panes that were screwed to the frame with a sealing strip between them. In these panes, the silica stones had to be dried approx. every second week.

- Panes that were fixed using magnetic strips. These panes were more leaky than the panes with sealing strips. In these panes, the silica stones had to be dried once a week. In addition, we had quite a few problems getting the glue on the magnetic strips to hold.

The bags with the silica stone are dried in the microwave on the lowest setting. (15 minutes for 15 bags of 7g.

The bags with the silica stone are dried in the microwave on the lowest setting. (15 minutes for 15 bags of 7g.

Both types of inner panes went beyond the aluminum frame, so we avoided moisture on the frame.

Double glazed windows

We now have replaced the windows in the wheelhouse with double-glazed windows, which are fixed in a frame made of PVC. The frame is relatively thick and insulates exceptionally well. Expensive (well over DKK 60,000) for 13 windows, of which the front 4 are in 8 mm toughened glass on the outside and the rest in 6 mm toughened glass on the outside. All are in 4 mm toughened glass inside. But really good. We have enjoyed a winter with no moisture on windows or frames, and good heating comfort. In addition, we also had a window made that can be opened, which we already have benefited from many times.

For the small windows in the boat, we continue with lexan inner panes (now screwed on). Since these windows are significantly smaller, the moisture problem here is not quite so big.

The double glazed windows were made to order from a Dutch company: Topwindows

Double glazed windows II

The windows in the main cabin had begun to leak, and the plexiglass cracked, so it was about time for new windows.

We agreed that we wanted windows with real glass.

The additional price for buying double-glazed windows rather than single-layer glass is about 1/3, so when it is a houseboat, the saving in energy consumption covers this additional price for double-glazed windows. And we get rid of condensation and trouble with inner panes.

The double glazed windows are also this time made to order by Topwindows

Before

After